WeChat:切换按钮及底部微信

WeChat:切换按钮及底部微信

Guidelines for the Operation of Medical Wastewater Treatment Process Plan

The relevant medical wastewater of first - and second level hospitals such as urban health centers and county level hospitals mainly consists of domestic sewage, bed surgeries, and laboratory tests. Blue One Environmental Protection Company has integrated the relevant process solutions of the medical wastewater treatment industry and adopted the long-range Blue One Intelligent Control System to ma

The relevant medical wastewater of first - and second level hospitals such as urban health centers and county level hospitals mainly consists of domestic sewage, bed surgeries, and laboratory tests. Blue One Environmental Protection Company has integrated the relevant process solutions of the medical wastewater treatment industry and adopted the long-range Blue One Intelligent Control System to make the operation of the medical wastewater treatment system more stable and greatly enhance the purification effect of wastewater treatment.

After the sewage is collected through pipelines, it first flows into the regulating tank through mechanical grilles to remove soft entanglements, large solid particles, and floating objects in the sewage, thereby protecting the service life of subsequent water pumps and reducing the workload of system treatment. The grid well is a brick concrete structure, and this process uses mechanical grids with a spacing of 5mm between grids.

After being treated by mechanical grilles, the sewage enters the regulating tank for the regulation and homogenization of water quantity and quality, ensuring the balance and stability of organic matter concentration in the subsequent biochemical treatment system. A pre aeration system is also installed for oxygenation and stirring to prevent the accumulation of particulate matter in the sewage due to long-term sedimentation, which also has a certain degradation effect on organic matter in the sewage and improves the pre-treatment capacity of the entire system.

A lift pump is installed in the regulating tank to lift the uniformly treated sewage to the anaerobic tank for treatment. The regulating pool adopts automatic control of floating ball liquid level. When the water level reaches the required level, the lifting pump works automatically. The floating ball liquid level adopts high opening and low stopping, and is intelligently controlled by PLC electronic control.

Due to the high content of organic nitrogen and compounds in sewage, they will appear in the form of ammonia nitrogen during biodegradation. Therefore, the indicators of ammonia nitrogen discharged into water will increase, and ammonia nitrogen is also a pollution control indicator. Therefore, an anaerobic tank is added before the contact oxidation tank. The anaerobic tank can utilize the nitrate brought in by the reflux mixture and the organic carbon source in the influent for denitrification, reducing NO2- and NO3- in the influent to N2 to achieve denitrification. Degradation of ammonia nitrogen while removing organic matter, equipped with efficient bio elastic packing and hydrolysis acidification function. The anaerobic tank decomposes difficult to degrade large molecules in organic matter into easily degradable small molecules, providing favorable conditions for subsequent biochemical processes;

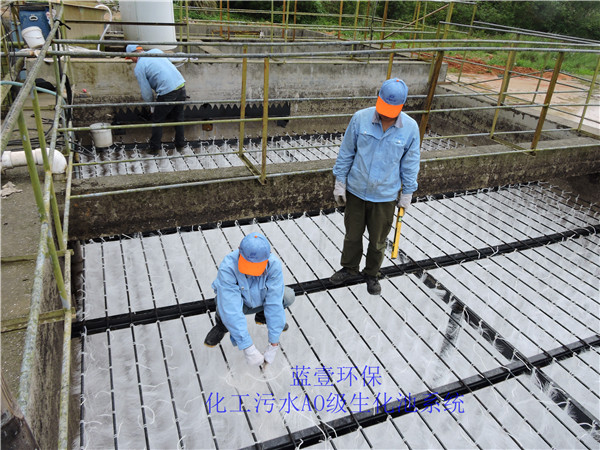

The contact oxidation tank is the core part of this sewage treatment, divided into two stages: anaerobic and aerobic. In the first stage, under high organic load, a large number of microbial communities of different species attached to the packing participate in biochemical degradation and adsorption, removing various organic substances from the sewage and significantly reducing the organic content in the sewage. In the later stage, under low organic load conditions, the action of nitrifying bacteria degrades ammonia nitrogen in sewage under sufficient oxygen conditions, while also reducing the COD value in sewage to a lower level, thus purifying the sewage. The pool consists of a pool body, packing material, water distribution device, and oxygenation and aeration system.

Easy to hang film, corrosion-resistant, and does not clump or block. The filling material can freely stretch in the water, cutting the bubbles in multiple layers, which relatively increases the aeration effect;

The pool is divided into two stages to degrade water quality into gradients, achieving good treatment effects. At the same time, corresponding diversion and turbulence measures are designed to make the overall design more rational.

The aeration pipeline in the pool is made of good national standard materials, which are corrosion-resistant. The aerator uses a 215 rotary mixer aerator, which is not blocked and has a high oxygen utilization rate;

【Related articles】

【Related Products】

-

Telephones:0371-88912366 0371-88912399

-

Service Hotline:4006096637(technology)

-

Address:Unit 303, Building 5, Zhangwuzhai No.2 Courtyard, Sequoia Road, Zhengzhou High tech Zone, Henan Province

-

Add WeChat

home

home

WeChat

WeChat

telephones

telephones